Welcome to our Company

Welcome to our Company

• Single Acting with relief and release valve

• Collapsible Handle

• Qmax: Upto 5cc/stroke

• Pmax: Upto 700 bar

• Duel Piston, with Automatic change over

A) Qmax: 49cc/stroke Pmax: 30bar

B) Qmax: 5cc/stroke Pmax: 700bar

• Fixed displacement, Bi-Directional Pump

• With 3, 5 or 7 Pumping elements

• Options: Open and Close execution type

• With or without Extension shaft

• Qmax:: Upto 13.6 lpm @1440 rpm

• Pmax:: Upto 550bar

• Double Pumping Sections, with option of combining both discharges

• Fixed displacement, Bi-Directional Pump

• With 3, 5 or 7 Pumping elements

• Options: Open and Close execution type

• With or without Extension shaft

• Qmax:: Upto 27.2 lpm @1440 rpm

• Pmax:: Upto 550bar

• Fixed displacement, Bi-Directional Pump

• With 5 or 7 Pumping elements

• Options: Open and Close execution type

• With or without Extension shaft

• Qmax: : Upto 25.8 lpm @1440 rpm

• Pmax:: Upto 400bar

• Double Pumping Sections, with option of combining both discharges

• Fixed displacement, Bi-Directional Pump

• With 5 or 7 Pumping elements

• Options: Open and Close execution type

• With or without Extension shaft

• Qmax: Upto 51.6 lpm @1440 rpm

• Pmax: Upto 400bar

• Direct acting with guided cushioned poppet

• Cartridge, Threaded and Subplate types

• Sizes: NG 06, NG 10, NG 20

• Qmax:: Upto 160lpm @1440 rpm

• Pmax Set: Upto 700bar

• Pilot operated seat type

• Low pressure overrides, remote controlibility

• Option: Solenoid unloading

• Subplate & Threaded type

• Sizes: NG 10, NG 20, NG 30

• Qmax: Upto 400lpm @1440 rpm

• Pmax Set: Upto 315 bar

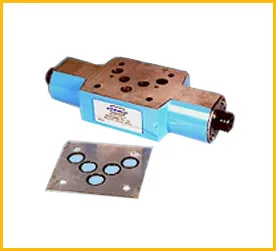

• Modular construction

• 4 models available

• Qmax: Upto 30 lpm  @1440 rpm

• Pmax Set: Upto 315 bar

• Two stage spool type relief / reducing valve cartridges

• Low pressure override

• 4 pressure range setting available

• Available with option of Set Screw and Hand Knob

• Two stage spool type valve cartidges

• Low pressure override

• Direct Operated Pressure Relief Valve

• Direct Operated Pressure Reducing Valve

• Pilot Operated Pressure Relief Valve

• Pilot Operated Pressure Reducing Valve

• Designed for Double Pump Hi-Low System.

• Consists of High and Low Relief valves and Check Valve.

• Solenoid Unloading optional.

• Seat Type

• Free Flow from B to A

• Leakproof closure from A to B upto determined pressure

• Pressure Compensated type, with reverse free flow option

• Stroke limiter optional

• For dividing into dual flow from single source into 50:50 ratio

• Throttle cum check valve, Non Pressure Compensated type

sizes : NG 06, NG 10

• Seat type Valve. free flow in A to B direction and leak proof closure in opposite direction.

• Threaded and Subplate mounting type

• Seat type valve with option of Piloting internally and externally

• Threaded and Subplate mounting available

• Double Pilot Operated Check Valve also available

• Available with Check on A or B or both

• Direct Operated Check Valve

• Bypass Check Valve

• Pilot Operated Check Valve

• Connects to either A or B whichever is at Higher Pressure level, Isolating the other

• Threaded and Subplate mounting available

• For prefilling and Exhausting Large hydraulic cylinders

• Can be used as Anticavitation Check Valve

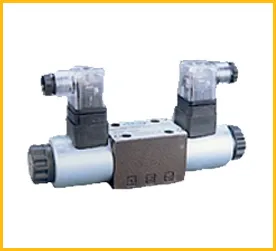

• 5 Chamber Body design for low pressure drop and better performance

• Balanced spool design

• Spring and Detent Options

• 5 Chamber Body design for low pressure drop

• Spring and Detent Options

• Available in NG 06, NG 10, NG 20, sizes

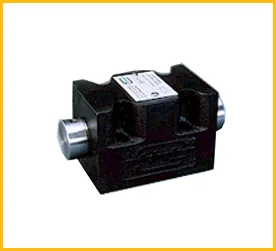

• Hydraulic Operated D.C. Valve

• Available in NG 10 & NG 20 sizes

• Pilot control by Solenoid optional

• Designed for Single Acting cylinder to hold pressure

• Ensures smooth decompression prior to return of the cylinder ram

• Hand Lever Opted Type in 10 & 20 Sizes

• Solenoid Opted Type in 20 size

• Quick exhaust option available in size NG20

• With built-in relief valve, check valve

• Spring and detent type

• Head Rotation in 90*4 positions possible

• For High Pressure application at low flow

• Used where ZERO leak is required

• Piston Type with Non-adjust pressure difference

• Subplate, Threaded and Face mountings

• Six adjustabe Pressure Range available

• Designed to control hydraulic or motor

• With built-in Relief

• Provision Pressure Measurement, filtration

• Suitable for cavities machined as per DIN 24342

• Fast response, low internal leakage and high flow handling capacity

• Functions like Check valve, Direction Control, Unloading valve, Throttle Valve can be achieved by proper selection of cartridge

• Covers for Cartridge are available for various functions like Standards, Relief, Shuttle, Unloading with solenoid, Proportional relief etc.

• Joysticks

• Foot Pumps

• Brake Valve

• Lock Valve

• Side Shift Lock Valves